Six Ways to Optimize your Project Outcomes with Design Tools

As you know, designing efficient structures while keeping costs in check is critical for a successful project, but it’s not easy. With tools and resources like Vulcraft’s Online Design Tools, however, you can work smarter, not harder. Below are six ways Design Tools can help streamline your workflow, optimize costs, and help efficiently design safe and cost-effective projects.

1. STREAMLINING THE SPECIFICATION PROCESS

Finding the right products for a project used to require hours spent with paper catalogs. Now, you can input your project-specific information into Vulcraft’s Design Tools and get tailored results instantly. This is especially helpful for handling complex loading scenarios, saving you both time and effort. With these tools, you can eliminate guesswork, save time by quickly getting the answers you need, and have complete confidence that your design meets project requirements.

2. PROJECT OPTIMIZATION THROUGH PRODUCT SELECTION

The ability to quickly evaluate multiple design options is a big deal when you’re trying to optimize both cost and performance. The Joist Wizard tool lets you compare cost ratios of different products, so you can make informed decisions fast. Input your parameters and get the most cost-effective options without compromising quality or performance.

3. CUSTOMIZATION FOR UNIQUE PROJECT REQUIREMENTS

Special loading scenarios can present several challenges, but Vulcraft’s Design Tools can help by specifying products for each project’s unique needs. For example, when dealing with non-uniform loads, Design Tools analyze the project and provide custom solutions, so your designs are both efficient and effective.

4. CREATING A SEAMLESS WORKFLOW

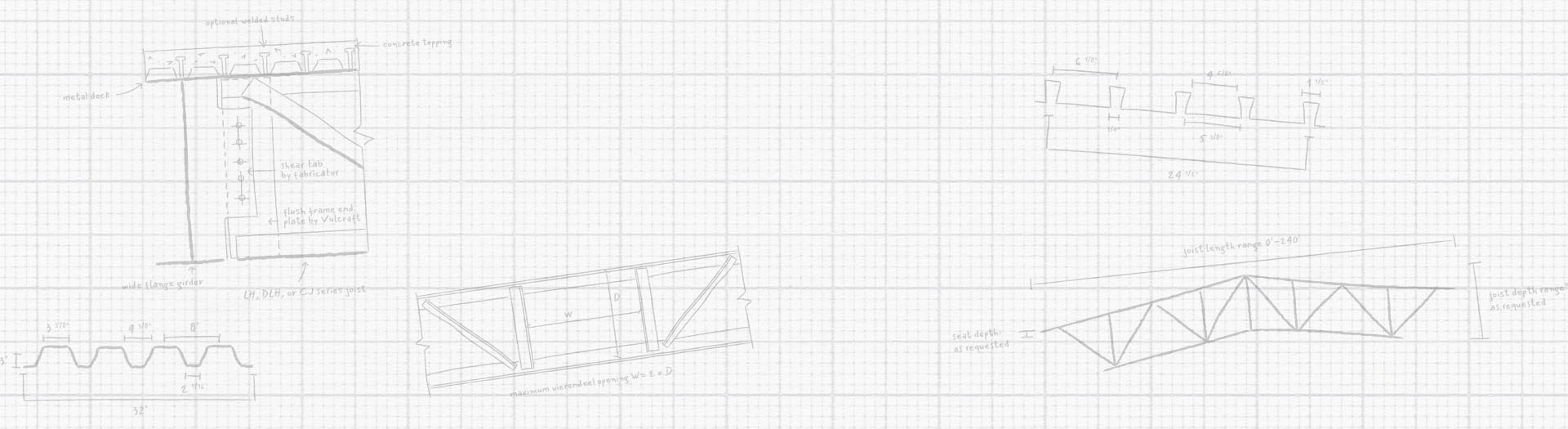

Design tools integrate with popular BIM software packages like Tekla and Revit, eliminating the need for manual data entry. These tools also support special joist profiles, allowing for virtually any project-specific geometry. Additionally, joist schedules for communication of complex loading scenarios can be automatically generated when using these tools.

5. ACCESSING EXPERT SUPPORT AND RESOURCES

Knowing that access to support is invaluable, Vulcraft offers customized guidance from our sales and engineering teams. We provide lunch-and-learn sessions tailored to engineering firms’ specific needs and interests and offer deep insights into both the tools and products we offer. During these sessions, engineers are encouraged to ask questions and gain a better understanding of the capabilities of Vulcraft products and how Design Tools can help them maximize those capabilities, ensuring maximum value for their projects.

6. GENERATING COMPREHENSIVE REPORTS FOR DOCUMENTATION

Since accurate and detailed documentation is crucial to the design process, Design Tools produce customized reports that include all underlying calculations. These reports can also be easily integrated into design files, making future reference easy and improving overall project success.

By using our Online Design Tools, you can streamline your processes, optimize costs, and evaluate designs more efficiently. We’re here to support you every step of the way, helping you achieve the best outcomes for your projects.

About the author

Douglas Eicher, P.E. has worked in the structural steel industry for 5+ years, with a specialty in the design of open-web steel joists and steel deck. He earned a Bachelor of Science in Civil Engineering, with a minor in Mathematics, from Purdue University - Fort Wayne in 2019. He currently works as a structural research engineer with the Nucor - Vulcraft Group, where he specializes in the development of innovative products, services, and software tailored to open-web steel joist and deck systems.